In modern seamless underwear, footwear, reflective materials and other fields, TPU hot melt adhesive film is increasingly being used. Its performance far exceeds that of ordinary adhesive films, but why? Next, we will explain in detail from the aspects of structure, raw materials, environmental protection, etc.

1. What is TPU hot melt adhesive film and why choose imported raw material formula?

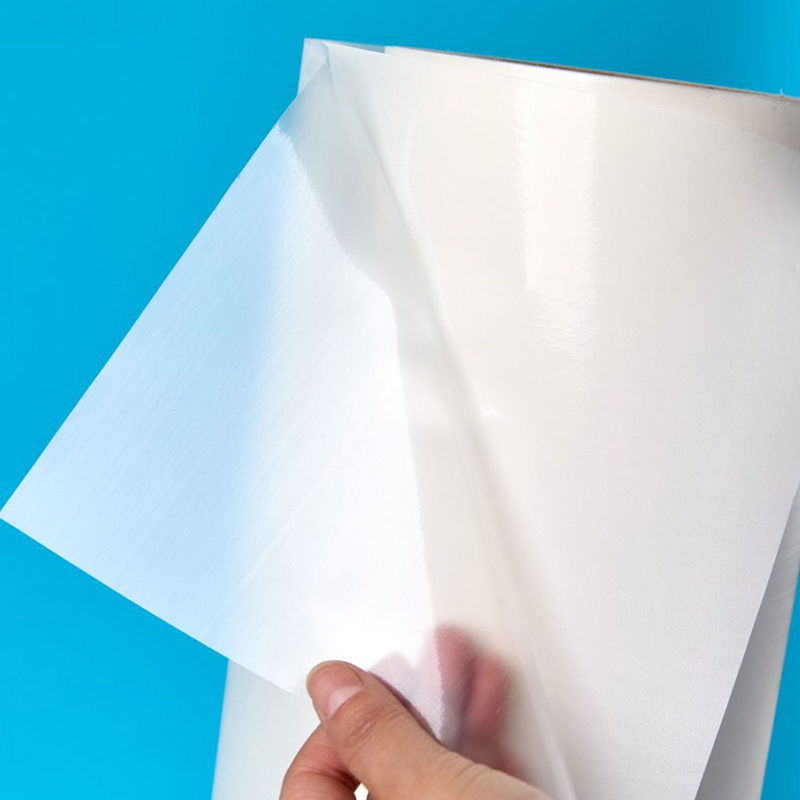

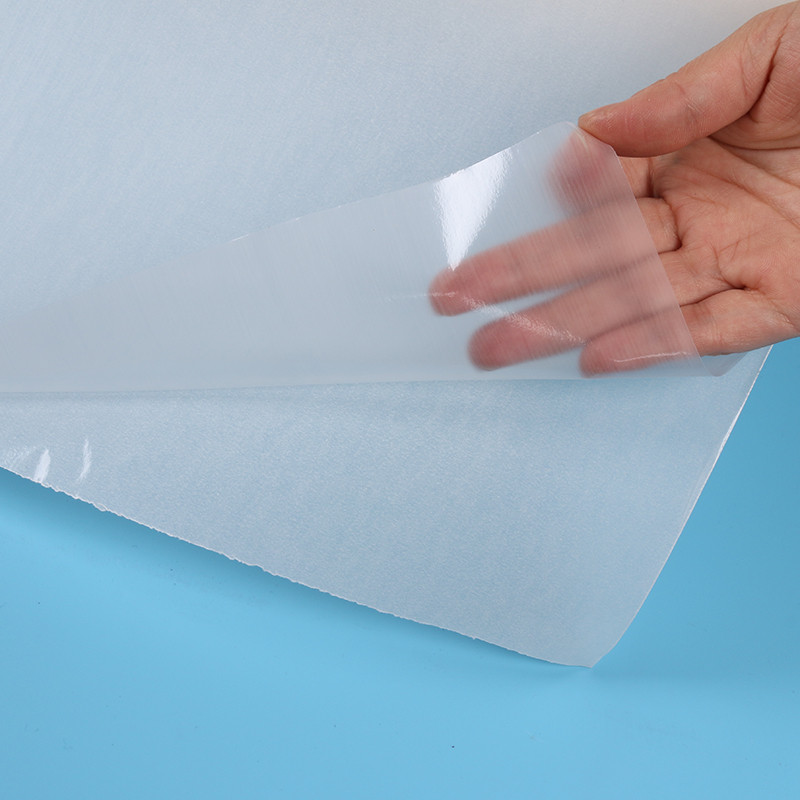

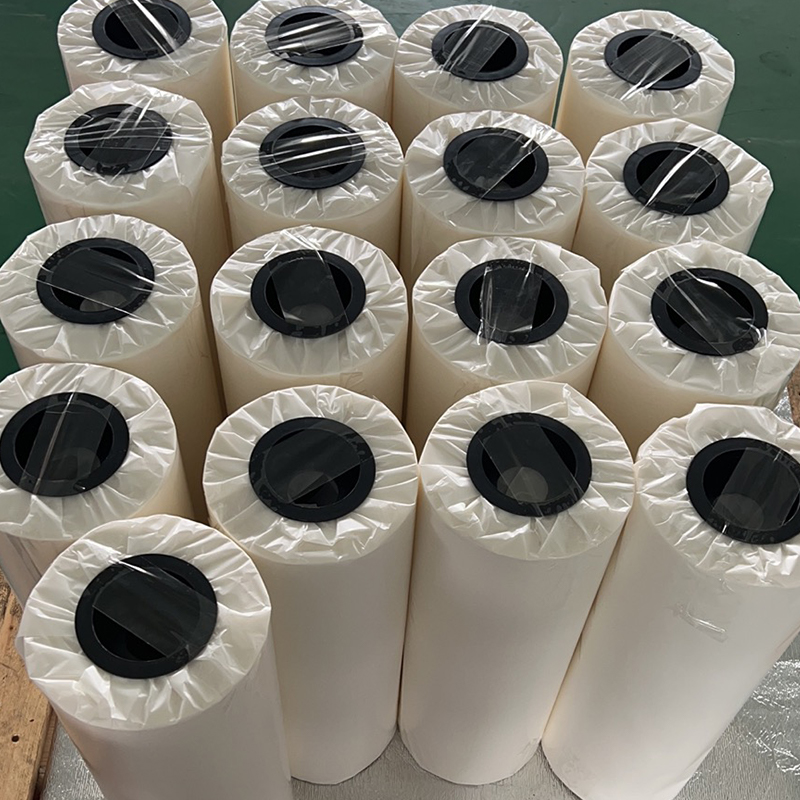

TPU hot melt adhesive film is a solid film produced by hot melt adhesive technology. Its bottom layer is attached with release paper, forming a two-layer structure of hot melt adhesive film and release paper. Anhui Haita New Materials Technology Co., Ltd. uses imported raw material formula to ensure that the product has excellent elasticity and waterproof function. This formula makes TPU hot melt adhesive film more durable in practical applications and is suitable for seamless underwear, footwear, reflective materials and other fields.

2. What is the essential difference between TPU hot melt adhesive film and ordinary film?

Ordinary adhesive film has a certain viscosity at room temperature, while TPU hot melt adhesive film has no viscosity at room temperature. It needs to be heated to the melting point of the adhesive layer and the adhesive layer melts to show strong viscosity. This design gives it the following advantages:

The thickness of the adhesive layer is uniform, and the lamination effect is better;

The hot pressing temperature is moderate and the operation is simple;

The bonding strength is high and the finished product is durable.

This kind of structural advantage allows TPU hot melt adhesive film to have a stable performance in the high-end manufacturing industry.

3. Why is TPU hot melt adhesive film the first choice for seamless underwear, footwear, and reflective materials?

Seamless underwear has extremely high requirements for elasticity and fit, footwear needs to be wear-resistant and washable, and reflective materials require waterproof and anti-aging. TPU hot melt adhesive film has become the preferred material in the above fields due to its excellent elasticity and waterproof function. For example, in the seamless underwear production line, after being heated by hot pressing equipment, TPU hot melt adhesive film can be firmly bonded to the fabric and maintain a good feel and appearance.

4. TPU hot melt adhesive film and EVA hot melt adhesive film, how to choose more environmentally friendly?

Many people are concerned about environmental protection. EVA hot melt adhesive film is an environmentally friendly adhesive, and its odor mainly comes from the polymer compound itself, which does not mean it is harmful. TPU hot melt adhesive film is also an environmentally friendly product. It does not release harmful substances during the heating process and meets the high environmental protection standards of modern manufacturing. Compared with the two, TPU hot melt adhesive film performs better in terms of washing resistance, water resistance and elasticity, so it is more suitable for high value-added products such as seamless underwear.

Anhui Haita New Materials Technology Co., Ltd. ensures that TPU hot melt adhesive film products achieve a good balance between environmental protection and practicality by continuously optimizing the production process.

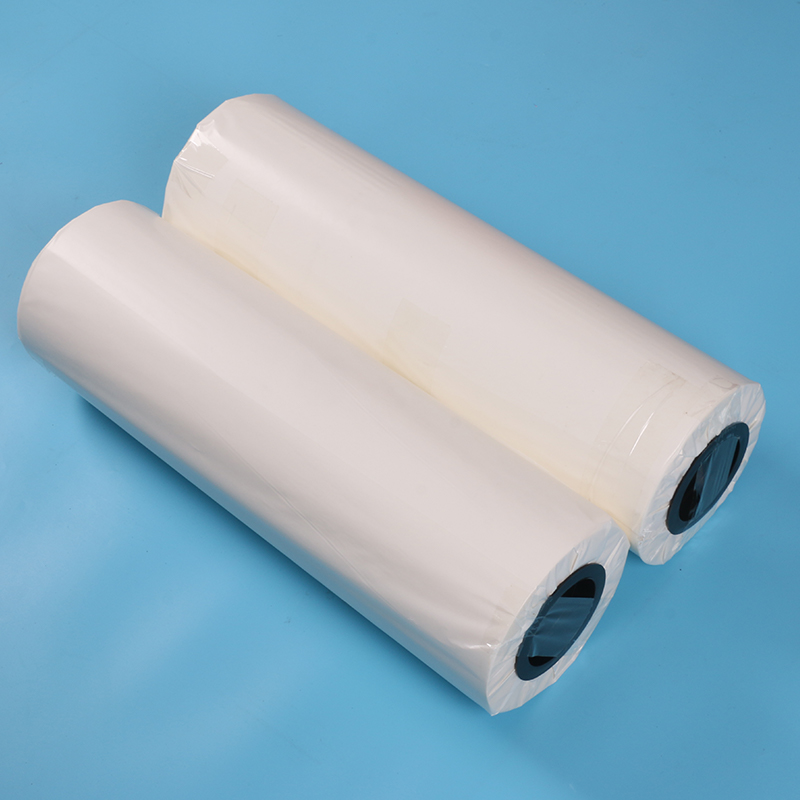

5. How to customize the TPU hot melt adhesive film specifications that suit you?

The width, thickness and length of TPU hot melt adhesive film can be customized according to specific needs. Different application scenarios have different requirements for the thickness and size of the film layer:

Seamless underwear: thinner and softer specifications;

Shoe materials: slightly thicker specifications;

Reflective materials: wide widths that need to be specially customized.

It is recommended to consult professionally according to the hot pressing temperature of the equipment, material properties and terminal product requirements when purchasing to obtain the best use effect.

English

English 中文简体

中文简体 Türk

Türk