Why can embroidered hot melt adhesive film gradually replace paper backing paper embroidery?

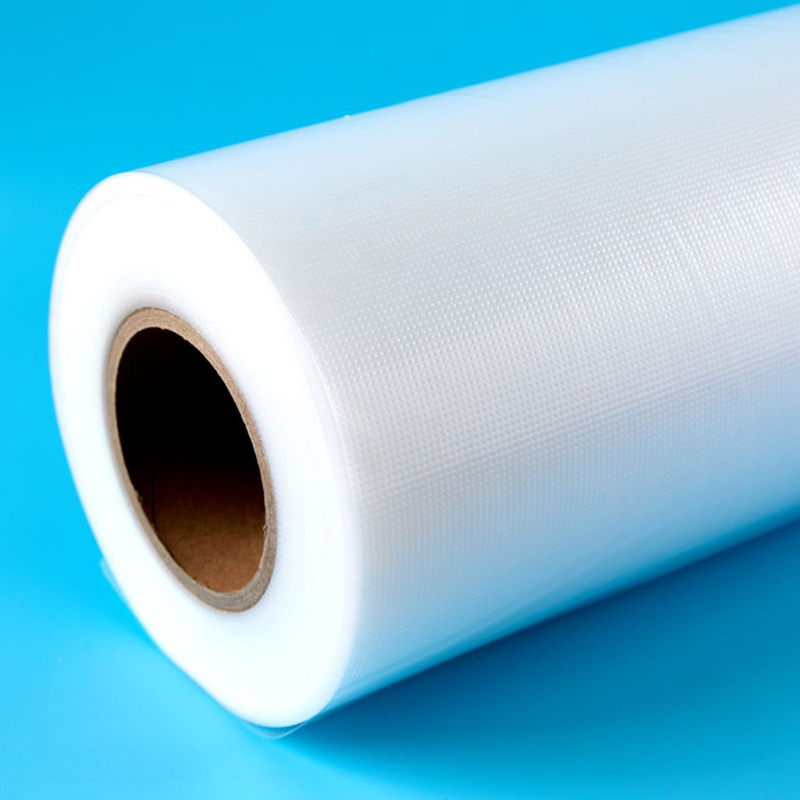

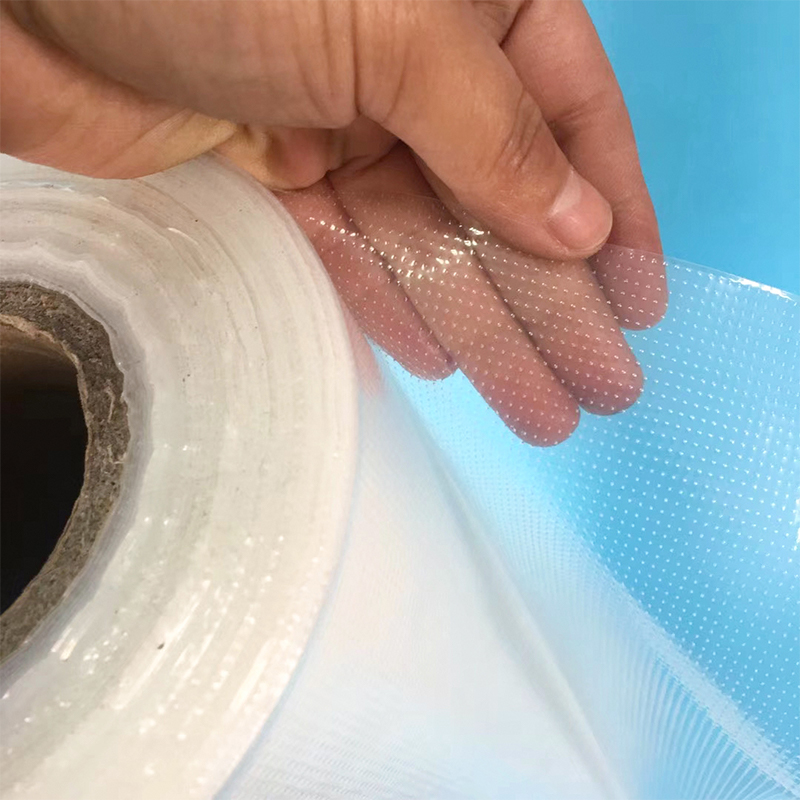

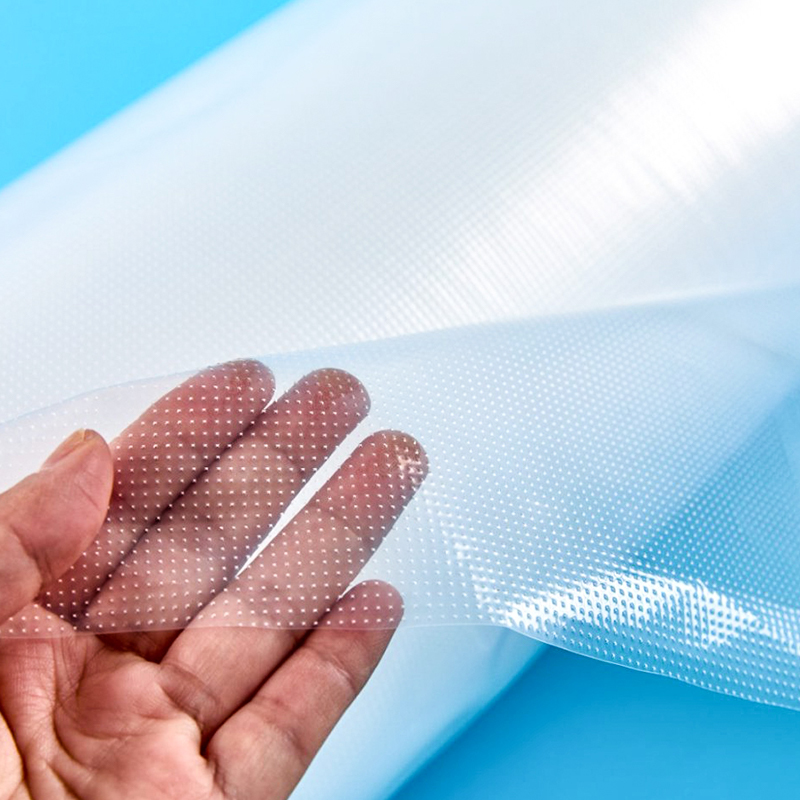

The embroidered hot melt adhesive film produced by Anhui Haita New Material Technology Co., LTD. is made of POLYOEFIN, environmentally friendly materials and film pressure reducers. The company has an independent R&D room and advanced equipment to ensure product quality from the source. The embroidered hot melt adhesive film produced does not contain formaldehyde, will not degrade slowly, has no residue, and is friendly to the environment and human health. Paper backing paper embroidery may have problems such as paper waste and ink pollution. This film conforms to the current trend of environmentally friendly production. The company's embroidered hot melt adhesive film is easy to peel off and is suitable for various fabrics. It performs well in the field of children's clothing embroidery with high requirements. It does not cause skin sensitivity and can meet the safety requirements of children's clothing directly contacting the skin. The adhesive film can improve the quality and added value of the embroidery finished product, such as making the embroidery pattern more three-dimensional and the edges more neat. In actual production, the embroidered hot melt adhesive film can adapt to the high-speed production rhythm. The company is equipped with large-scale production lines and high-precision equipment to ensure the stable supply of products. Using embroidered hot melt adhesive film simplifies the operation process of workers and reduces the tedious steps of handling paper backing paper.

What is unique about embroidered hot melt adhesive film in terms of raw material formula?

The company's R&D team is composed of many professionals with rich experience in polymer science, material engineering and film production. They carefully select raw materials, which have good stability and flexibility. With environmentally friendly materials, it is ensured that the product meets environmental standards from the source, no harmful gases are released during the production process, and no pollution is caused to the environment after use. The film pressure reducer is specially added to the formula, which can effectively improve the physical properties of the film, reduce the internal stress of the film, and enable the film to maintain stable performance under different temperature and humidity environments, and is not prone to brittle cracking or deformation. Relying on the company's self-developed ERP management system, the entire process from raw material procurement, production and processing to finished product inspection is under strict monitoring. Each batch of raw materials is strictly tested to ensure that the formula ratio is accurate, so as to ensure that each roll of embroidered hot melt adhesive film has stable and excellent performance, providing customers with reliable product quality assurance.

What measures are there to ensure the quality of embroidered hot melt adhesive film in the production process?

Anhui Haita New Material Technology Co., LTD. has a series of advanced equipment such as large-scale water-soluble film production lines, water-soluble non-woven fabric production lines, blown film production lines, and hot melt film coating production lines. These equipment can accurately control key parameters such as temperature, pressure, and speed in the production process. For example, in the blown film production line, the thickness uniformity of the film can be accurately controlled, so that the thickness error of the produced embroidered hot melt adhesive film is extremely small. The R&D laboratory is equipped with various small experimental equipment, where the R&D team can conduct a large number of experiments and tests. In the new product development stage, the performance of the film samples produced under different process parameters is tested by simulating the actual production and use environment. According to the test results, the production process is continuously optimized to ensure that the final product quality meets or even exceeds the industry standard. From the inspection of raw materials entering the factory, to the online inspection during the production process, to the comprehensive inspection of the finished product, every link has strict quality standards. High-precision slitting machines, cutting tables, rewinding machines and other equipment are used to inspect the appearance and size of finished products, and advanced testing instruments are used to test the chemical and physical properties of products.

How can embroidered hot melt adhesive film meet the dual needs of safety and beauty in the application of children's clothing embroidery?

Anhui Haita New Material Technology Co., LTD.'s embroidered hot melt adhesive film, with its environmentally friendly formula, does not contain harmful substances such as formaldehyde. The company strictly follows environmental protection standards in the production process, from raw material screening to production process control, to ensure product safety in all aspects. After testing and certification by authoritative organizations, it ensures that the products meet the safety requirements of children's clothing production, so that parents can rest assured. The company's embroidered hot melt adhesive film is easy to peel off. In the process of children's clothing embroidery, it can make the edges of the embroidery pattern neat and clear, without residual glue stains affecting the appearance. The adhesive film can fit well with various children's clothing fabrics, whether it is soft pure cotton or elastic Lycra fabric, it can ensure the three-dimensional sense and fullness of the embroidery, making the embroidery decoration of children's clothing more delicate and vivid, and improving the overall beauty and quality of children's clothing. The company has a strong production capacity, with a daily production capacity of 500,000 square meters. It can provide embroidered hot melt adhesive film of different thicknesses and widths according to the diverse needs of children's clothing designers. Designers can choose the appropriate specifications of adhesive film according to the complexity of the embroidery pattern and the characteristics of the fabric to achieve more creative designs.

English

English 中文简体

中文简体 Türk

Türk