Introduction to Garment Hot-Melt Adhesive Film

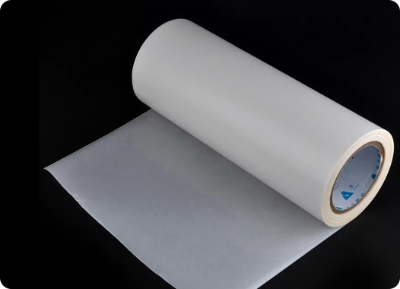

What is Garment Hot-Melt Adhesive Film?

Garment hot-melt adhesive film is a type of thermoplastic adhesive material designed for bonding fabrics and other textile materials. It melts when heat is applied, creating a strong and durable bond between layers of fabric. This technology is widely used in modern garment manufacturing to replace traditional sewing methods for certain applications, allowing for seamless finishes and efficient production.

Benefits of Using Garment Hot-Melt Adhesive Film

- Increased Production Efficiency: Reduces sewing time and labor costs by providing instant adhesion during heat pressing.

- Improved Garment Durability: Creates consistent bonds that maintain strength after multiple washes.

- Clean and Seamless Finish: Eliminates visible stitches in areas where a smooth look is required, such as sportswear and innerwear.

Applications of Garment Hot-Melt Adhesive Film

Seamless Clothing Bonding

Garment hot-melt adhesive film is widely used for seamless bonding in garments. It allows manufacturers to join fabrics without visible stitches, which enhances both comfort and aesthetics. Typical applications include:

- Sportswear: moisture-wicking fabrics for athletes

- Lingerie: smooth, skin-friendly adhesion without discomfort

- Functional jackets: windproof and waterproof seams

Elastic Fabric Applications

Elastic fabrics such as Lycra, spandex, and stretch polyester benefit from hot-melt adhesive films because they maintain flexibility after bonding. Key considerations include:

| Parameter | Standard Film | Elastic Film |

| Adhesion Strength | Medium | High |

| Elastic Recovery | Low | High |

| Wash Resistance | Moderate | High |

Eco-Friendly Applications

Eco-friendly hot-melt adhesive films are solvent-free and VOC-free, reducing environmental impact. They are ideal for companies focusing on sustainable production while maintaining high-quality bonding. Applications include:

- Garments: children’s clothing, innerwear

- Home textiles: curtains, pillowcases

- Other industries: electronics packaging requiring clean bonding

Heat Press Techniques

Proper heat pressing is critical for achieving optimal adhesion. Important factors include:

- Temperature: 120–160°C depending on fabric type

- Pressure: 3–5 bar for uniform bonding

- Time: 10–30 seconds per section depending on film thickness

Applications include garment labels, badges, patches, and areas where traditional sewing is inconvenient.

Low-Temperature Hot-Melt Adhesive Films

Low-temperature films are designed for delicate materials such as polyester, leather, and sensitive synthetics. Advantages include:

- Prevents fabric deformation

- Reduces risk of heat damage

- Maintains strong adhesion at lower temperatures (90–120°C)

Choosing the Right Garment Hot-Melt Adhesive Film

Factors to Consider

- Fabric type compatibility: cotton, polyester, leather, stretch fabrics

- Heat and pressure requirements: select films suitable for machine capabilities

- Environmental considerations: eco-friendly and solvent-free options

Comparison of Different Types of Garment Hot-Melt Adhesive Films

| Type | Temperature Range | Adhesion Strength | Elasticity | Eco-Friendly |

| Standard Film | 120–160°C | Medium | Low | No |

| Low-Temperature Film | 90–120°C | Medium | Medium | Optional |

| Elastic Film | 120–150°C | High | High | Optional |

| Eco-Friendly Film | 120–160°C | Medium | Low | Yes |

Tips and Best Practices

Application Techniques for Seamless Bonding

- Use uniform heat and pressure across all bonded areas

- Test small samples before full-scale production

Maintaining Fabric Integrity During Bonding

- Monitor temperature to prevent scorching

- Use low-temperature films for delicate fabrics

Troubleshooting Common Issues

- Incomplete adhesion: increase heat or pressure slightly

- Wrinkling: adjust pressing time or use a protective release liner

- Fabric damage: switch to low-temperature adhesive films

Conclusion

Garment hot-melt adhesive film offers versatility, efficiency, and a clean finish for modern garment production. By selecting the appropriate type of film and applying best practices, manufacturers can achieve high-quality results across various fabric types.

FAQ

1. What fabrics are best suited for Garment Hot-Melt Adhesive Film?

Garment hot-melt adhesive film can be used on cotton, polyester, spandex, Lycra, and leather. Selecting the right type of film ensures proper adhesion without damaging the fabric.

2. Can eco-friendly Garment Hot-Melt Adhesive Film replace traditional adhesives?

Yes, eco-friendly films are solvent-free and VOC-free, offering a sustainable alternative while maintaining strong adhesion. Anhui Haita New Material Technology Co., LTD provides eco-friendly adhesive films suitable for large-scale production.

3. How to ensure long-lasting adhesion without damaging fabrics?

Choose the appropriate film type (standard, elastic, low-temperature, or eco-friendly), control heat and pressure, and perform sample tests. Anhui Haita New Material Technology Co., LTD offers technical support and a wide range of adhesive films with daily production capacity of 500,000㎡, factory area of 10,000㎡, and annual material consumption of 5,000 tons to meet industrial-scale needs.

English

English 中文简体

中文简体 Türk

Türk